Welcome to the official website of the electrodeposition simulator, "EDESFEM".

News

- (2025-12-01) RCCM (the distributor)'s EDESFEM product information page (in Japanese) has been renewed.

- (2025-04-30) We contributed an article explaining EDESFEM (copyright belongs to JSCES) to "Computational Engineering and Science", Vol. 30, No. 2 (in Japanese).

- (2024-05-22) EDESFEM received "The Technology Prize" for FY2023 from the Japan Society for Computational Engineering and Science (JSCES).

- (2023-05-27) RCCM exhibited EDESFEM at a booth in "Automotive Engineering Exposition 2023".

Overview

Brief

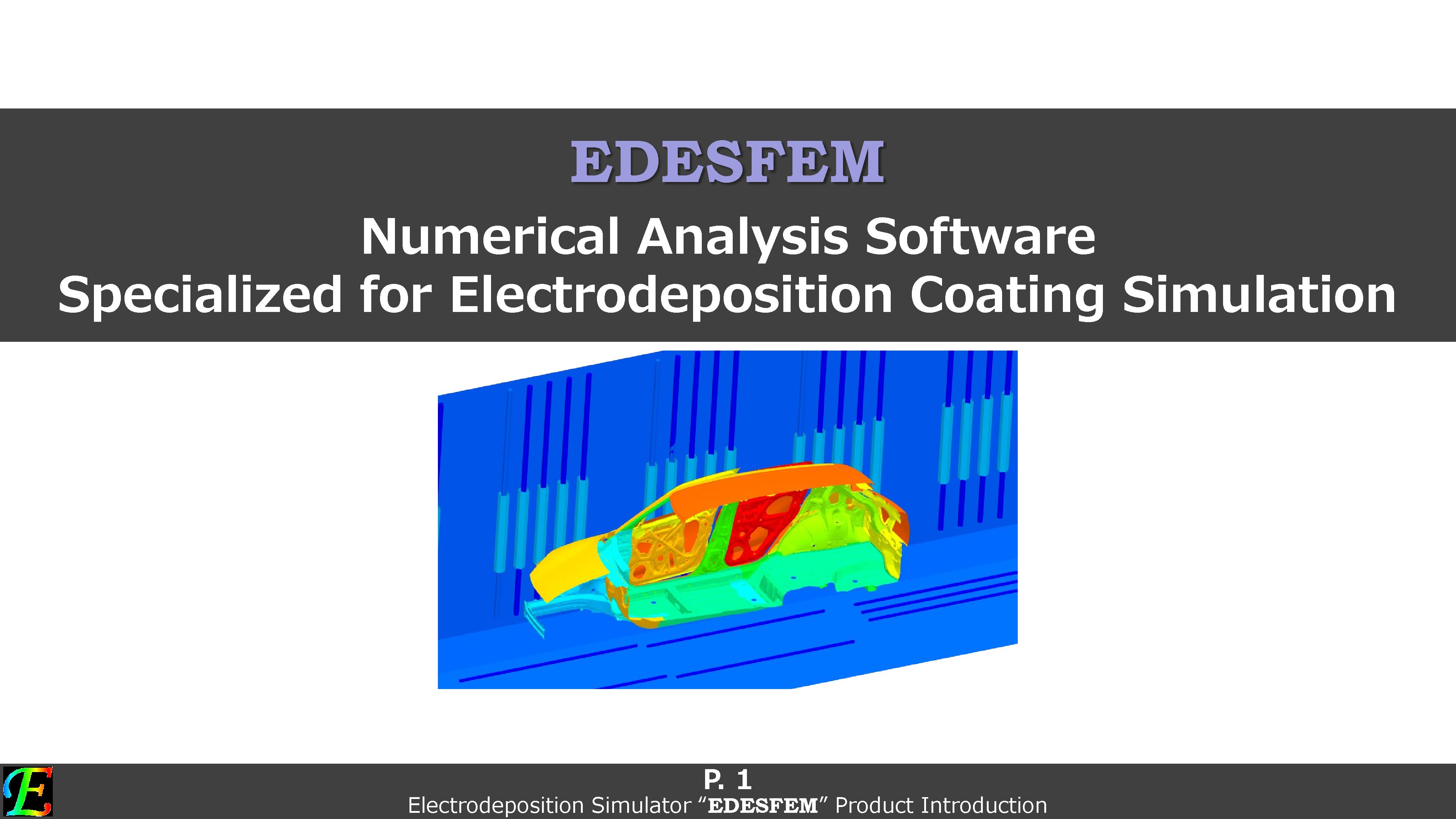

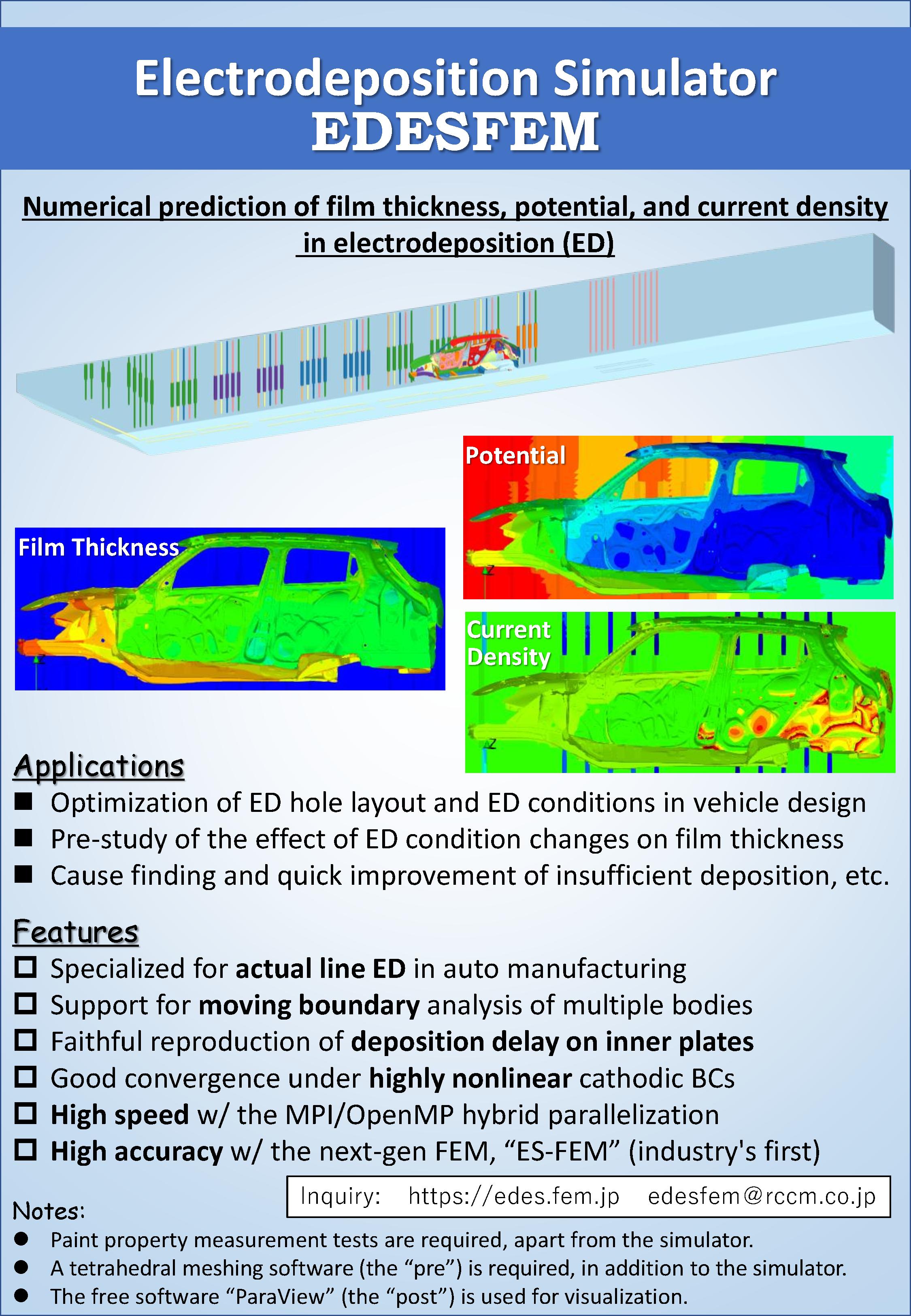

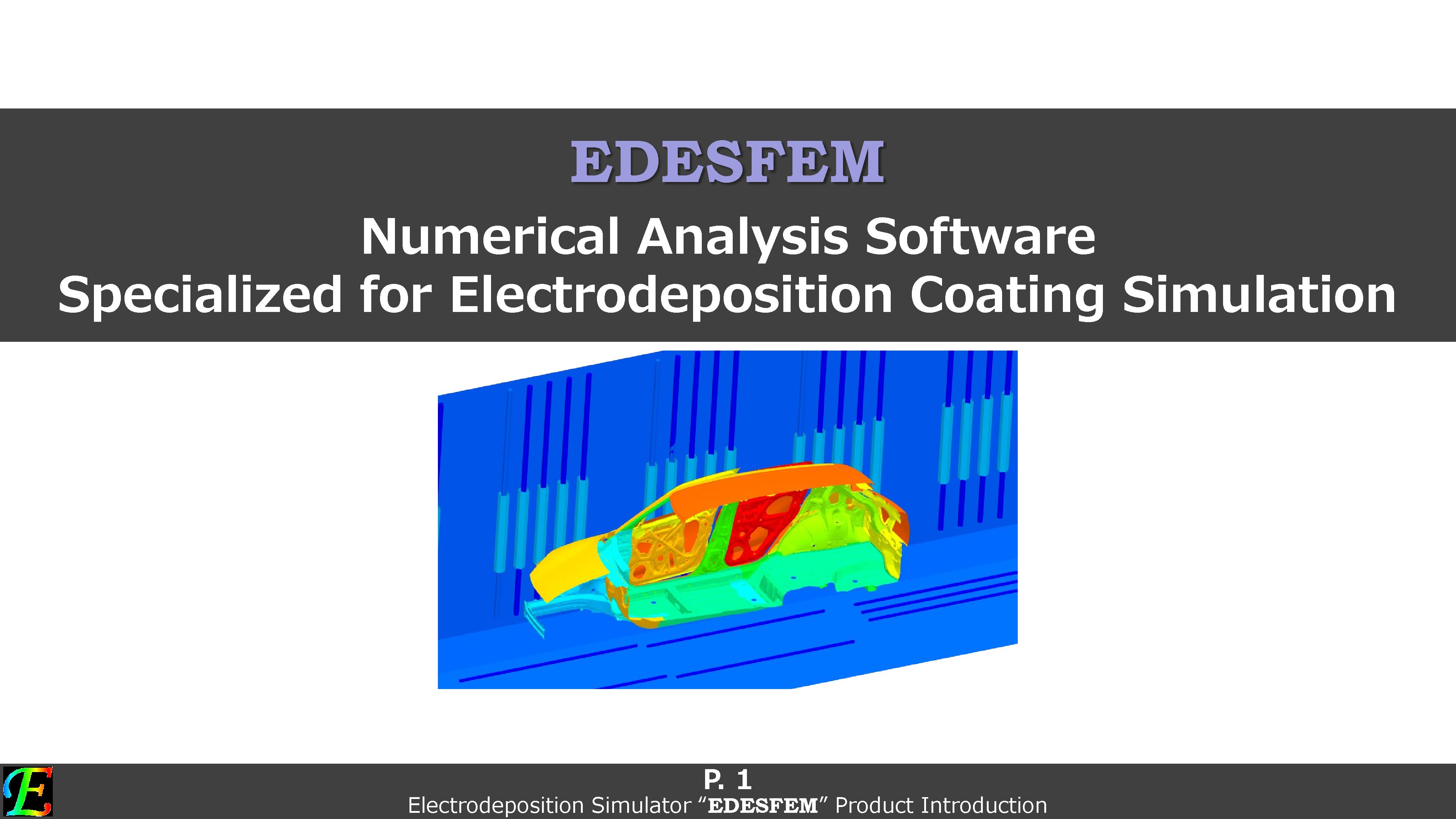

"EDESFEM" (/edésfem/) is a single-function numerical analysis software specialized for the simulation of electrodeposition (ED) coating.

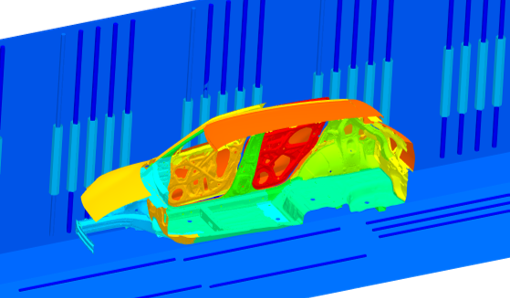

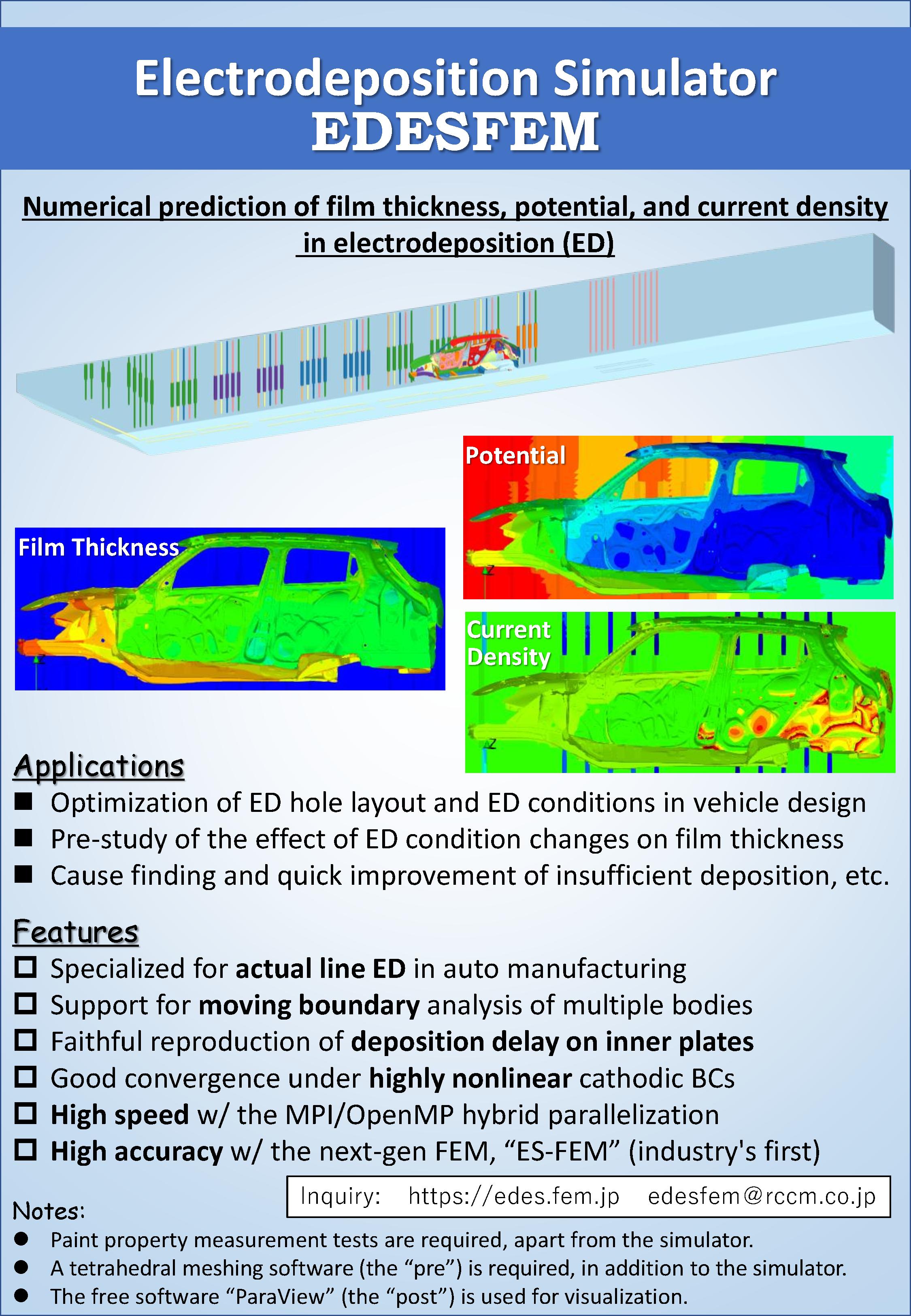

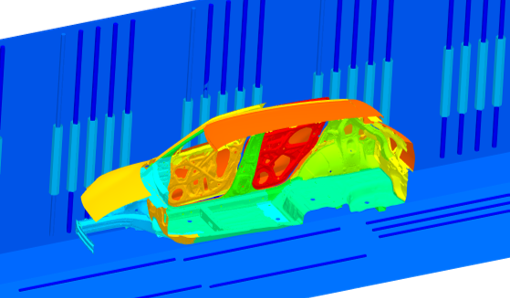

It can computationally predict the time histories of the distributions of film thickness, electric potential, and current density in cationic electrodeposition coating on automobile bodies and parts.

We have experience in the combinations of various steel plates (cold commercial (SPCC); hot commercial (SPHC); hot-dip zinc-coated (GA)), chemical conversion treatments (zinc phosphate; zirconium), and cationic ED paints (gray for body; black for parts; high/ultra-high throwing power).

Applications

- Optimization of ED hole layout and ED conditions in vehicle design.

Preliminary calculations for designing the position and size of ED holes and the settings of the power source can reduce the trial-and-error labor required at the start of new car model production.

- Pre-study of the effect of ED condition changes on film thickness.

The effects of changes in power source setting, takt time, electrode type and placement, paint itself, etc. can be evaluated in advance.

- Cause finding and quick improvement of insufficient deposition.

When a deposition problem occurs, ED simulation facilitates the cause investigation and leads to short-term improvement.

Features

- Specialized for actual line ED in auto manufacturing.

For the convenience of automotive CAE engineers, EDESFEM is daringly developed as a non-general-purpose software.

- Support for moving boundary analysis of multiple bodies.

The situation where multiple car bodies get into an ED pool can be reproduced so that the influence of the leading/following bodies can be evaluated.

- Faithful reproduction of deposition delay on inner plates.

The latest numerical ED model based on detailed laboratory tests is implemented.

- Good convergence under highly nonlinear cathodic BCs.

A stabilized Newton's method is adopted so that Newton's iteration is less likely to fail even when a strongly nonlinear BC with an S-shaped polarization curve is given.

- High speed with the MPI/OpenMP hybrid parallelization.

You can enjoy the benefits of the latest multi-core CPUs in multi-node HPC environments.

- High accuracy with the next-gen FEM, "ES-FEM" (industry's first).

By employing the edge-based smoothed finite element method (ES-FEM), the computational accuracy is almost equivalent to that of quadratic elements even with 4-node tetrahedral meshes.

Notes

- Paint property measurement tests are required, apart from the simulator.

Please feel free to contact us for inquiries about ED lab experiments.

- A tetrahedral meshing software (the "pre") is required, in addition to the simulator.

Please prepare a meshing software which can output in CFX5 format (.cfx5) or Legacy Fluent format (.msh.gz), such as ANSYS ICEM CFD or ANSYS Fluent Meshing. There are also case examples of using STAR-CCM+ and ANSA.

- The free software, ParaView (the "post"), is used for visualization.

Visualization is possible with the industry-standard free software.

Leaflet

JPEG version is

here.

PDF version is

here.

Slide

HTML version is

here.

PPTX version is

here.

PDF version is

here.

Price

Annual License Fee (including technical support within 48 hours):

2,420,000 JPY with tax (=2,200,000 JPY without tax + 220,000 JPY tax), where the price is subject to change without notice.

Links

- Research Center of Computational Mechanics, Inc. (RCCM)

- Yuki ONISHI's Website (Institute of Science Tokyo, School of Engineering, Dept. of Systems and Control Engineering)

- Yuki Onishi.

"Automotive Electrodeposition Coating Simulation using Edge-based Smoothed Finite Element Method",

The 4th International Conference on Computational Engineering and Science for Safety and Environmental Problems (COMPSAFE), 2025.

- [In Japanese] Yuki Onishi,

'Electrodeposition Simulator "EDESFEM"' (copyright belongs to JSCES),

Computational Engineering and Science, Vol. 30, No. 2, pp. 4951-4955, 2025.

- [In Japanese] Takeshi Kashiyama, Kenei Shin, Akira Sato, Hisashi Monchusho, Wataru Motonaga, Yuki Onishi.

"Validation of Numerical Electrodeposition Model for Various Paints and Pretreated Steel Plates and Its Application to Actual Carbody Simulation",

Transactions of Society of Automotive Engineers of Japan, Vol. 54, No. 6, pp. 1320-1325, 2023.

- Yuki Onishi.

"Application of Edge-based Smoothed Finite Element Method to Electrodeposition Simulation aiming for Super-linear Mesh Convergence in Film Thickness Accuracy",

The 14th International Conference on Computational Methods (ICCM), 2023.

- Yuki Onishi,

"Application of Edge-based Smoothed Finite Element Method to Large-scale Electrodeposition Simulation for Automobile Manufacturing Line",

The 15th World Congress on Computational Mechanics & The 8th Asian Pacific Congress on Computational Mechanics (WCCM-APCOM), 2022.

- Yuki Onishi,

"Accurate electrodeposition simulation of automobile bodies with edge-based smoothed finite element method using 4-node tetrahedral meshes",

The 3rd International Conference on Computational Engineering and Science for Safety and Environmental Problems (COMPSAFE), 2020.

- [In Japanese] Kai KITAMURA, Yuki ONISHI, Takeshi KASHIYAMA, Kenji AMAYA.

High Accuracy Automotive Electrodeposition Simulation Based on Basic Experiments Replicating Actual Manufacturing Line Conditions,

Transactions of JSCES Paper, Vol. 2019, No. 20190014, 2019.

- [In Japanese] Takeshi Kashiyama, Yuki Onishi, Kai Kitamura, Kenji Amaya.

Development of High Accuracy Electrodeposition Paint Film Thickness Simulation and Application for Actual Carbody Model,

Transactions of Society of Automotive Engineers of Japan, Vol. 50, No. 5, pp. 1481-1486, 2019.

- FrontISTR commons.

FrontISTR v5.5 Release Note,

2023.

JPEG version is here.

PDF version is here.

JPEG version is here.

PDF version is here.

HTML version is here.

PPTX version is here.

PDF version is here.

HTML version is here.

PPTX version is here.

PDF version is here.

rccm.co.jp Please replace the image of the at sign with text.

rccm.co.jp Please replace the image of the at sign with text.